When Should Designers Use Crossed Roller Bearings?

September 23rd, 2020 by David Casillo. Product NewsTip 1: Is precision a key requirement of the application?

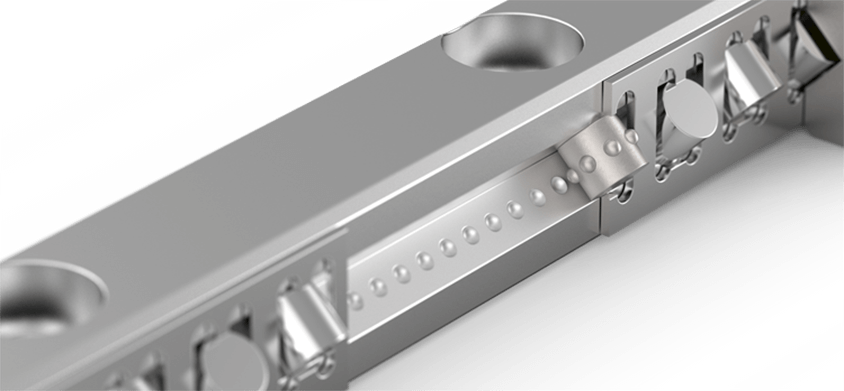

Crossed rollers use a series of cylindrical bearings or rollers set at 90 deg to one another to form a V which fits into a slot on the rail. Each roller provides an entire line of contact as opposed to just the point or two of contact provided by liner actuators using ball bearings. The larger contact area means the rollers deform less than recirculating ball bearings under the same load and slide ways are also stiffer. The increased stiffness gives them more precision and consistency in their movements.

Tip 2: Will heavy loads be moved in the application?

The increased contact between the rollers and the moving rail that give crossed roller bearing their precision also increases the load they can carry. Some of these crossed roller bearings support loads up to 20,000 N. If the load exceeds the crossed-roller bearing’s capacity, companies can use rollers with smaller diameters which lets more rollers be used and thereby increases the load capacity.

Tip 3: Does the application call for moving loads vertically or up and down inclines?

Without a slippage control mechanism, the cage or retainer holding the rollers or ball bearings in place can move when the slide way is mounted vertically or inclined, or it if makes many short, fast movements. If the cage “creeps” out of position, it can restrict the rails motion and then rolling elements are slipping, not rolling. Slipping creates metal-to-metal contact, wearing the rollers, shortening the slide ways life and lowering its accuracy.

The unique and elegant solution to this slippage is the STUDROLLER. It has a center roller with studs running around the circumference.

This eliminates any cage creep so the slide way can be mounted in any orientation. It has been shown to survive hundreds of millions of cycles without failure.

Tip 4.What if the application will be used in settings where noise is problem, like hospitals or clinics?

Cross rollers replace recirculating ball bearings in these linear-motion devices. Ball bearing make lots of noise when shuttling through their raceways, and this can be a problem. Crossed rollers do not move, they remain in place as the rail rides over top of them. Therefore, the motion is smooth and quiet. There also aren’t any vibrations to add noise or put wear on components.

WATCH THE STUDROLLER IN ACTION

Categories

Keywords

Copyright© 2024 Isotech, Inc. All rights reserved.