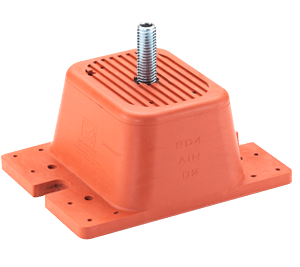

Model VLM Leveling Isolator, Neoprene/Elastomeric Floor Mounted Non-Seismic

Type VLM Isolators utilize oil-resistant neoprene elastomers to provide effective shock and vibration control for all types of general metal working and processing machinery. Built-in-leveling feature provides height adjustment to compensate for unequal mounting deflection or floor irregularities. Ribbed design of mounting base provides non-skid surface, eliminating the need for bolting to a floor. Cuts machine installation time from hours to minutes. Four sizes provide load capacities up to 12,000 pounds per isolator.

Benefits

Very wide static load range of 50-12,000 lbs. offers solutions for almost any production floor application

Built-in leveling provides height adjustment for floor irregularities and/or unequal isolator deflection

Ribbed isolator base provides a non-skid surface - eliminating the need to bolt machinery to the floor

Corrosion-resistant coating on all metal surfaces provides extra durability

Nominal frequency of 10 Hz provides structure-borne noise attenuation in even the most challenging installations

Applications

Grinders, jig bores, lathes

Milling machines

Punch presses, shears, brakes

Printing presses

Processing equipment