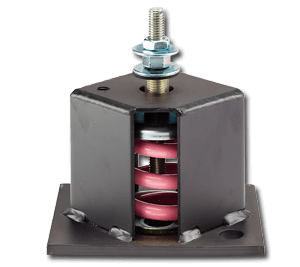

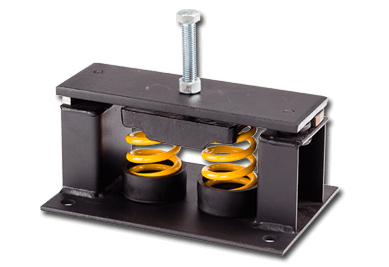

Model MSS Isolators, Spring Floor Mounted Seismic

MSS Series Isolators, combine our open spring mountings within a rugged welded seismically rated steel housing. To minimize, the code required seismic loads on the isolated equipment, the housing is designed to limit equipment motion to ¼ in horizontal directions due to wind or seismic loads. The MSS type incorporates an external adjustment bolt that also acts as a single point attachment to the equipment. The top housing incorporates seismic restraint bolts that pass through the lower housing and are protected in all directions by an elastomeric bushing. Combined, the restraint bolts and bushings act as internal snubbing devices for the isolator. To achieve accurate installation heights, The VMC Group has incorporated an installation spacer between the lower and upper housing. After the equipment is installed and the isolators are properly adjusted, there will be no difference between the installed and operating heights.

Mechanical equipment is attached to the MSS style product by using the adjustment bolt of the isolator to fasten to the equipment’s designated mounting locations. Low frequency T-Series steel springs are located within the housing and are seated in an elastomeric acoustical cup that provides high frequency attenuation and eliminates metal-to-metal contact. The spring and cup design allows for easy replacement or changing of springs when required and all springs are color-coded for ease of identification in the field. The lower housing incorporates an oversized base plate that spreads the anchor bolt over a wider area – this is specifically designed to increase seismic restraint capability. As an additional benefit, ease of installation is also achieved by allowing easy access to the anchor bolts. These isolators are designed for installations in either concrete or steel and the base plates are pre-drilled with mounting holes to accommodate attachment to either. MSS Series Isolators are available with 1″ through 5″ deflection springs. Each style isolator has a load range of 50 lbs. to 19,500 lbs.

Benefits

Rugged steel housing serves as blocking during equipment erection

Housing offers no difference in elevation between installed and operating height

Installation spacer ensures accurate installation height and adjustment

Single point attachment

External adjustments for single point installations with interchangeable springs

Attachment/adjustment bolt of the isolator fastens to the equipments designated mounting locations

Housings are identical in height within each series

Easily accessible bolt holes permit simplified installation

Elastomeric acoustical cup eliminates high frequency vibrations

Color-coded springs permit ease of identification of load capacity

For use in most seismic and wind applications

Applications

HVAC and electrical equipment

Air handling units

Condensing units

Chillers

Pumps

Engine gensets

Seismic