The Importance of Precision Shafting in Improving Linear Motion System Performance

February 21st, 2024 by David Casillo. Product NewsWhen designing a linear motion system much of the focus is on the selection of the proper linear ball bearing, however, it is not the only element you must consider. In linear motion system engineering it is often said that “a better shaft means better linear motion performance.”

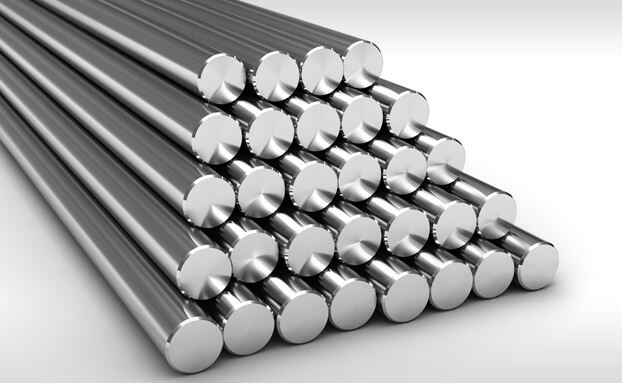

Precision ground shafts are used with bearings such as a slide bushing in order to obtain highly accurate linear motion. The design of the shaft plays a crucial role as the shaft performs as the inner race of the bearing system. The quality and accuracy of the shaft will directly affect the performance of the slide bushing. Thus, the bearing’s performance is directly influenced by the characteristics of the shaft.

Today, the availability of specialized materials and finishing techniques for linear motion shafting can present new opportunities for improving linear motion system performance. To get the most travel life from the shaft, it must offer a sufficiently hard surface, be perfectly cylindrical and straight with smooth surface finish. If not, the shaft will wear rapidly, offer reduced ball contact area, and can reduce the number of balls carrying the load. Any of these problems reduces the bearing’s performance in terms of load capacity and travel life.

Typical linear shafting is offered in a range of materials including carbon steel, chrome plated steel, stainless steel and other materials depending on the application requirements.

Isotech Precision Linear Shafting

Isotech’s Precision Linear Shafting is ideal for a wide range of linear motion applications. Our linear shafts are constructed from precision hardened and ground carbon steel or stainless steel and are available in a wide range of diameters and lengths. Isotech shafts are manufactured with an emphasis on quality and accuracy to ensure optimal performance, minimal maintenance and long life. They feature uniform hardness in both radial and axial directions along with high precision roundness, straightness, cylindricity and surface finish.

The Type W carbon steel shaft and Type WRV carbon steel shaft with hard chrome plating are made from materials Cf53 and Ck55 and are available in both inch and metric measurements, with diameters ranging from 1/4″ to 2″ (5 mm to 50 mm) and lengths of 3,000 mm or 6,000 mm.

The Type WRB stainless steel shaft is made from the material X46Cr13 and is both inch and metric measurements, with diameters ranging from 1/4″ to 2″ (5 mm to 50 mm) and lengths of 3,000 mm or 6,000 mm.

Linear Shafting Models & Specifications

Categories

Keywords

Copyright© 2024 Isotech, Inc. All rights reserved.