Isotech Linear Belt Drives and Actuators Are Now Available in Plug-and-Play and Standard Off-the-Shelf Configurations

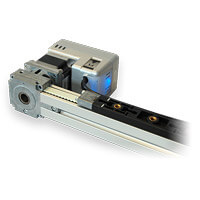

August 31st, 2011 by isotechinc. Product News Isotech Inc., a supplier of precision linear motion products, has announced the company is now offering a full line of off-the-shelf and plug-and-play linear belt drives and actuators. Off-the-shelf models are available in standard configurations for quick delivery, while plug-and-play models include an actuator, motor and PLC for out of the box operation for a variety of automation applications.

Isotech Inc., a supplier of precision linear motion products, has announced the company is now offering a full line of off-the-shelf and plug-and-play linear belt drives and actuators. Off-the-shelf models are available in standard configurations for quick delivery, while plug-and-play models include an actuator, motor and PLC for out of the box operation for a variety of automation applications.

Isotech’s standard and plug-and-play belt driven actuators allow buyers to select from a range of products with popular specifications. In addition, buyers are able to configure the product through options including single or double shaft types, preferred drive shaft location and a number of standard travel lengths up to 2,242 millimeters.

Both options are designed to provide an accurate, durable, maintenance free solution for linear motion applications.

“With the addition of the off-the-shelf and plug-and-play configurations, finding fast solutions for automation applications are easier than ever,” said Joe Casillo, president of Isotech. “Ideal applications for the plug-and-play and standard belt drives include university settings or automated robotics that perform simple tasks common in gantries and lifts.”

Isotech linear belt drives and actuators are available in travel lengths from 184 mm to 2242 mm, maximum speeds of 1,270 mm/sec to 15,240 mm/sec, and maximum load capacities of 25 lbs. to 2,500 lbs. Belt drives provide between 100 lbs. to 2,500 lbs. of force.

Steel and plastic bearings are available to meet most light-duty to extra heavy-duty motion applications. The steel bearings are supplied with lifetime lubrication while plastic bearings require no lubrication. Applications, even those that may require long travel, benefit from the steel concave rollers riding on chrome-plated steel rails for excellent positioning. Alternatively, a plastic coated needle bearing assembly offers the highest possible speeds and durability in tough applications that require a push-pull configuration.

“Our belt drives feature a steel reinforced polyurethane belt that helps deliver repeatable positioning by preventing belt stretching,” said Casillo of the actuators’ accuracy.

Casillo also points out no lubrication or maintenance is required when Isotech belt drives are used under normal operating conditions.

The Isotech belt driven actuator standard configurations accept NEMA 17, 23, and 34 motors and can be configured to accept other sizes.

In addition to the standard and plug-and-play configurations, customizable actuators and belt drive options are also available. Knowledgeable Isotech application engineers can be reached at 800-314-3332 for specifications and application information or additional information is available at www.isotechinc.com.

Categories

Keywords

Copyright© 2024 Isotech, Inc. All rights reserved.