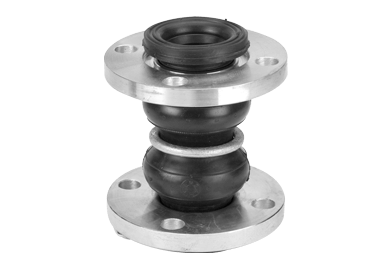

The Flex Connector Series includes single sphere connectors with floating flanges, and double sphere connectors with union threads. These connectors are designed to compensate for expansion, compression, transverse movement and angular deflection due to thermal changes in piping connected to rotating equipment. As a result, the connectors also reduce vibration and noise transmission.

The Flex Connector Series are molded of elastomer and synthetic fiber and are furnished with corrosion resistant steel floating flanges. The floating plate steel flanges are drilled to mate with companion flanges for simplified installation. These series accommodate operating temperatures to 240⁰F and operating pressures to 214 psi – making them suitable for pressure and vacuum service applications. Sizes range from 1 1/4″ to 20″ I.D.

Flex Connectors should be installed at the suction and discharge ends of each pump, and at the inlet and outlet of each chiller and condenser. When piping is not anchored, control rods must be installed at each connector to limit movement. The VMC Group offers control rods in several sizes that will withstand operating pressures up to 200 PSI.

Features & Benefits

Resilient, flexible connectors compensate for axial and lateral movement of equipment piping – maintaining noise and vibration isolation integrity

Elastomer and synthetic fiber design along with corrosion-resistant steel floating flanges provide flexibility, durability and long component life

Floating plate steel flanges drilled to mate with companion flanges provide simple installation

Choice of single or twin sphere designs offer a choice of suitable connectors for a variety of applications

Control rods, if necessary, are offered in several sizes that will withstand operating pressures up to 200 psi

Applications

Air handling units

Fans

Pumps

Chillers

Air compressors

HVAC equipment

Power generation

Electrical transformers

Motors