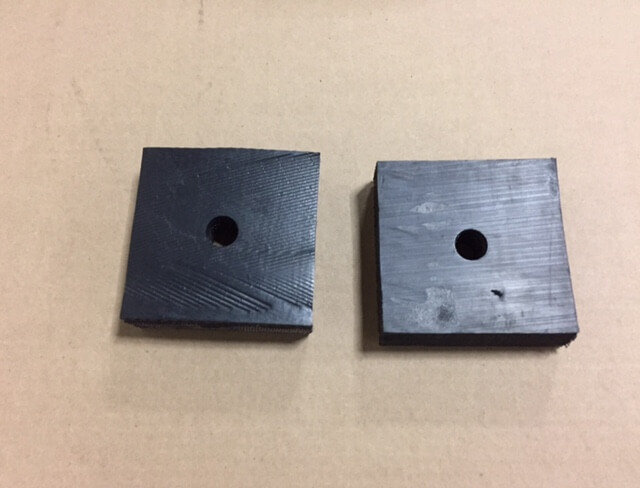

Machinery Vibration Pads made out of HIGH TENSILE AIRCRAFT TIRES

- Pads made out Aircraft Tire Rubber of 8000 psi Tensile Strength

- Rubber Reinforced with 6 to 10 ply Nylon Layers and lasts longer

- Used as Isolator Pads with OE Bus and Truck Manufacturers for decades

- Absorbs Vibration

- Withstands Cyclical Flexing

- Withstands Tough Applications: Snow Plow Cutting Edge, Snow Blower Paddle, Auto Lift Pads, and Mortar Mixer Rubber Blades

- Exceptional Tear Resistance and Abrasion Resistance – ASTM Standards

- Can be Custom Made to a maximum size of 120 in. by 10 in. by 1 in. thick

- Saves Significant money compared to any molded, extruded rubber & plastic parts

- Made in USA

We manufacture HIGH TENSILE TICOR rubber products using a unique process from Aircraft Tires for Industrial, Agricultural, Automobile, and Construction sectors for many decades.

Our rubber products can be engineered for your specific application. We can custom die-cut to meet your application requirements.

They are low cost with excellent tensile strength up to 8000 psi and with excellent abrasion & tear resistance.

They give significant savings when compared to molded, extruded rubber, plastic and polyurethane products.

TICOR parts and assemblies are being used in hundreds of applications where engineers require a versatile, low cost, durable rubber material that can transmit torque, absorb vibration, seal gaps against granular leakage, convey and spread materials, withstand cyclical flexing and allow for thermal expansion and contraction.

TICOR parts are ideally suited for a broad range of applications requiring high tensile strength, long flex-life and resistance to aging and abrasion. TICOR die-cut parts are produced in a variety of shapes and sizes and are found in many types of products ranging from high-volume consumer products to low-volume construction equipment.

TICOR parts and assemblies are being used in hundreds of applications where engineers require a versatile, low-cost, durable rubber material that can:

- transmit torque

- absorb vibration

- seal gaps against granular leakage

- convey and spread materials

- withstand cyclical flexing

- allow for thermal expansion and contraction

Typical applications for TICOR die-cut rubber parts include mounting pads, isolators, couplers, baffles, hangers, deflectors, end gate seals, straw spreader blades, conveyor flight paddles, snow thrower blades and snow plow deflectors.

Engineers have learned that parts made from the TICOR material has many of the properties of rubber, plastic and polyurethane, but at a fraction of the cost.

TICOR parts are produced by a unique mechanical method of recycling tires. Each tire is classified by size, number of plies and type of reinforcing material. Both beads are removed and the two sidewalls and center tread section are separated. The three segments are then machined to the proper thickness with a close tolerance range. After inspection, the TICOR parts are die cut to their specific size and shape.