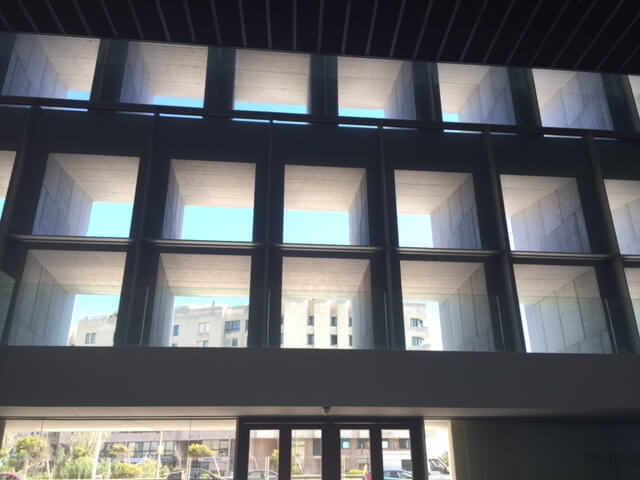

Architectural & Design Applications

A versatile material with virtually limitless design and architectural applications. As well as its unique appearance, it has sound absorbing properties making it ideal for applications requiring both sound absorption and beauty. It is used for Facades, wall cladding, ceiling tiles or dropped ceilings, restaurants, bars, offices, apartment buildings, showroom displays, Terrazzo flooring, signage, lighting fixtures, exhibits, and any application that you dare to imagine.

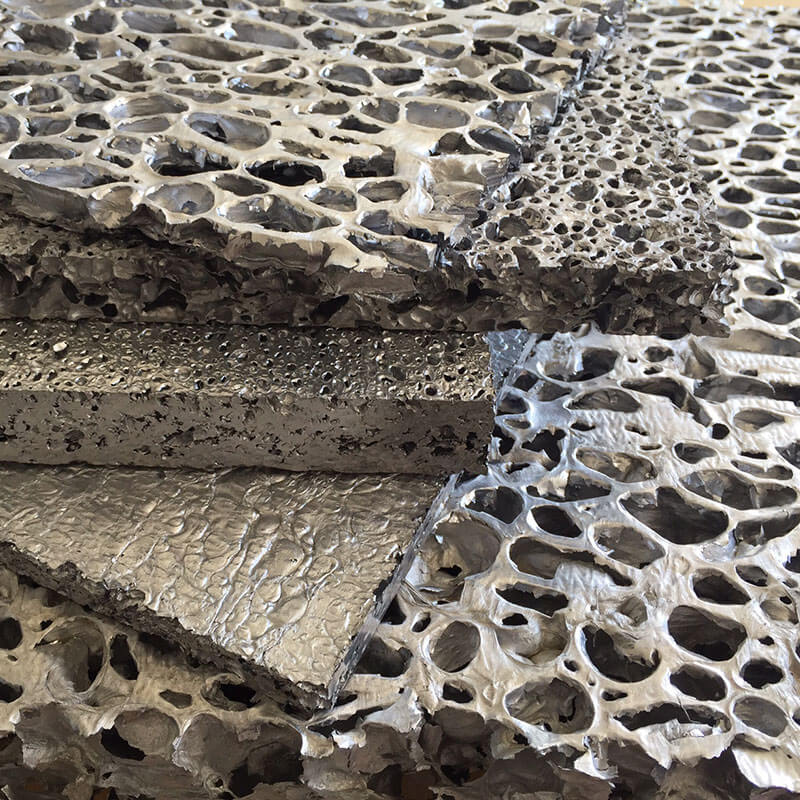

Aluminum foam creates strong yet lightweight panels. Similar in appearance to a metallic sponge, it is visually striking, with a modern dramatic look. For architecture, aluminum foam is produced in panels ranging in various densities, and in thicknesses from 12.7mm to 43.2 mm (custom available pending quantities). Standard versions are Small, Mid and Large.

The surface of each panel is either left in its solid natural form as produced, or undergoes surface preparations which provide many different appearances. Appearances as a solid surface “shimmering” look to a translucent “water froth” look, even custom designs. The 2 sides of each panel, identified as ‘top and/or bottom, look very different from each other.

Upon request, detailed information on product offering, application information, and technical specifications can be provided.

- Various versions are available for both interior and exterior applications

- Produced with up to 100% recycled content, and material is 100% recyclable

- Provides beauty, strength and lightweight acoustic solutions for a variety of creative opportunities

- Standard panel size is 1220mm W x 2440mm L (4’ X 8’) standard thickness of 12.7mm, 25.4mm or 43.2mm (1/2”, 1” & 1.7”)

- Panels are available in Small, Mid & Large cell versions

- The top and bottom of each panel type comes in two finishes – “Natural” which has a natural metallic skin or “Open” which exposes the cells on the panel surface

Additional Information

- Cellular cast aluminum foam, produced with a continuous casting method, with beautiful continuous skin on the surface of all panels

- Proven ability to supply large projects on time, on budget and meeting or exceeding quality standards

- Eco Friendly, 100 percent recyclable and produced using post-industrial aluminum

- Available in various decorative beautiful finishes; in Small, Mid or Large cellular structure

- Various foam densities between .14 g/cc and .52 g/cc

- Sound absorbing material, sound dampening, shock absorbent

- Ultra light material- Pending versions, 2.96 kg per M2 to 10.42 kg per M2 (.61 lbs per sq ft to 2.13 lbs)

- Heat insulating and resistant, and totally mold and mildew free

- Product does not collect dust, and bugs do not nest in aluminum foam (spiders, bees etc)

- Produced using post-industrial aluminum, 100% post-consumer aluminum recycled content, 100% recyclable, LEED

- Impact resistant, quality assurance, easy to move, easy installation

- Highly resistant to wind loads for exterior applications

- Class A flame rating with a flame spread of “0”

Technical info and Product Spec sheets available upon request

Aluminum Foam for Composite Panels

Aluminum foam can be used as composite panels for the Construction industry & Building Environments:

- Decorative or non decorative Acoustical panels for any acoustical solution including exterior highway or road acoustical barriers

- Design any commercial or residential high performance surface solution by adding aluminum foam as a backing or as a sandwich panel

- Create solid but yet “light weight” composite panels which do not decay, with anti mold and mildew qualities

- Composite panels for stone, marble, granite, ceramic, travertine, wood tile etc

- For new or existing buildings, exterior or interior Walls, flooring, signs, exhibits, lighting

- Architect clients create “Super insulated buildings”, by using fuel efficient “insulation aluminum foam composite solutions”

- Climate and Air quality controlled applications

- Subway ventilators, Air vents, moisture barriers, building components, crawlspace substrates

- Hospitals, Clean Rooms, Marine, underground composite panels, railcar chiller compartments

- Create lightweight moisture & thermal barriers, control corrosion, and vibration

- Insulation and Environmental control solutions

- Reduce heating and air conditioning requirements