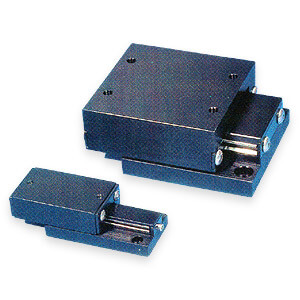

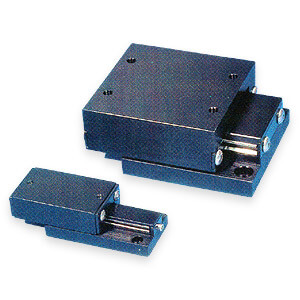

High Precision Crossed Roller Slides (Flange Base)

Series: HPRS2-FB, HPRSA2-FB, HPRS3-FB, HPRSA3-FB, HPRS4-FB, HPRSA4-FB, HPRS5-FB, HPRSA5-FB

- Load Capacity: 90 – 450 lbs.

- Travel: 1.0 – 10″

- Length: 2.00 – 15″

- Straight Line Accuracy: 0.0000405″ / inch of travel

- Positional Repeatability: .000020″

- Coefficient of Friction: 0.002 typical

- Construction: Aluminum carriage and base, hardened 400 series stainless steel rollers, shafts and pre-load gibs.

- Finish: Black anodize. Other finishes on request.

Isotech’s Flange Base High Precision Crossed Roller Slides offer the designer highly accurate travel characteristics. 0.000040″ per inch of travel with superior repeatability of 0.000020″. The base and carriage inner surfaces are ground to submicron tolerances while the mounting surfaces are flat to within 0.0001″ per inch. The standard low profile, high precision crossed roller slide incorporates a base which is surrounded by the carriage leaving little surface to attract and hold contaminants.

These slides utilize Isotech’s straight line design which allows lower friction characteristics along with the option to manipulate the preload to adjust to the needs of the application.

New larger widths and lengths up to 5.75″ wide and 15″ long increases the versatility of this design.

Installation into your system is simple. Counterbored holes in the base permit quick attachment to your assembly. Components attach to the carriage in the existing threaded mounting holes.

- Stable flanged base style.

- Superior accuracy and repeatability.

- Precision ground carriage and base.

- Corrosion resistant hardened stainless steel internal components.

- Bigger cross sections and lengths for heavy loads and large moving parts.

- Smooth low friction motion.

Model HPRSA2-1.5FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA2-1FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA2-2FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA2-3FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA3-1FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA3-2FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA3-3FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA3-4FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA3-5FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA4-2FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA4-3FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA4-5FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA4-6.5FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric

Model HPRSA4-9FB, High Precision Series Crossed Roller Slides (Flange Base) – Metric